JPE Brand Event | JPE x CTCI Product Application Forum

2024-12-25

Company Activity

The safety and reliability of equipment are of paramount importance. The product application forum between JPE and CTCI's subsidiary, CTCI ADVANCED SYSTEMS INC., focused on the core needs of the industry, delving deeply into material selection services and risk management in installation details. This exchange provided practical insights for ensuring safe production within the industry. As an expert in critical components such as instrument needle valves, ball valves, and tube fittings, JPE not only showcased its products during the meeting but also shared how professional material selection services and meticulous attention to installation details can effectively mitigate potential risks.

Material Selection and Certification: The First Line of Defense for Safety

Material Selection and Certification: The First Line of Defense for Safety

In any industrial environment, the choice of materials is critical to ensuring both safety and performance. However, material quality is not always visible to the naked eye, and different materials exhibit vastly different characteristics under various conditions. When precise tubing and the proper application of fittings and valves are implemented, the following benefits can be achieved:

1. Save installation time and costs.

2. Save maintenance time and costs.

3. Reduce the risk of pipeline leaks.

4. Avoid the need for future rework.

To help clients make the best choices, JPE provides detailed material selection standards and reference tools. These take into account multiple factors, such as external environmental conditions, corrosion resistance of the product, cost-effectiveness, and quality, combined with expert opinions in the field to create the most suitable customized solutions for clients. Additionally, international certifications are crucial indicators of product safety, such as ISO 15848 and ASTM F1387. These certification systems impose stringent requirements on product design, manufacturing, and testing, ensuring that the products operate stably in their intended applications and deliver reliable safety.

Installation Details: Building a Reliable System

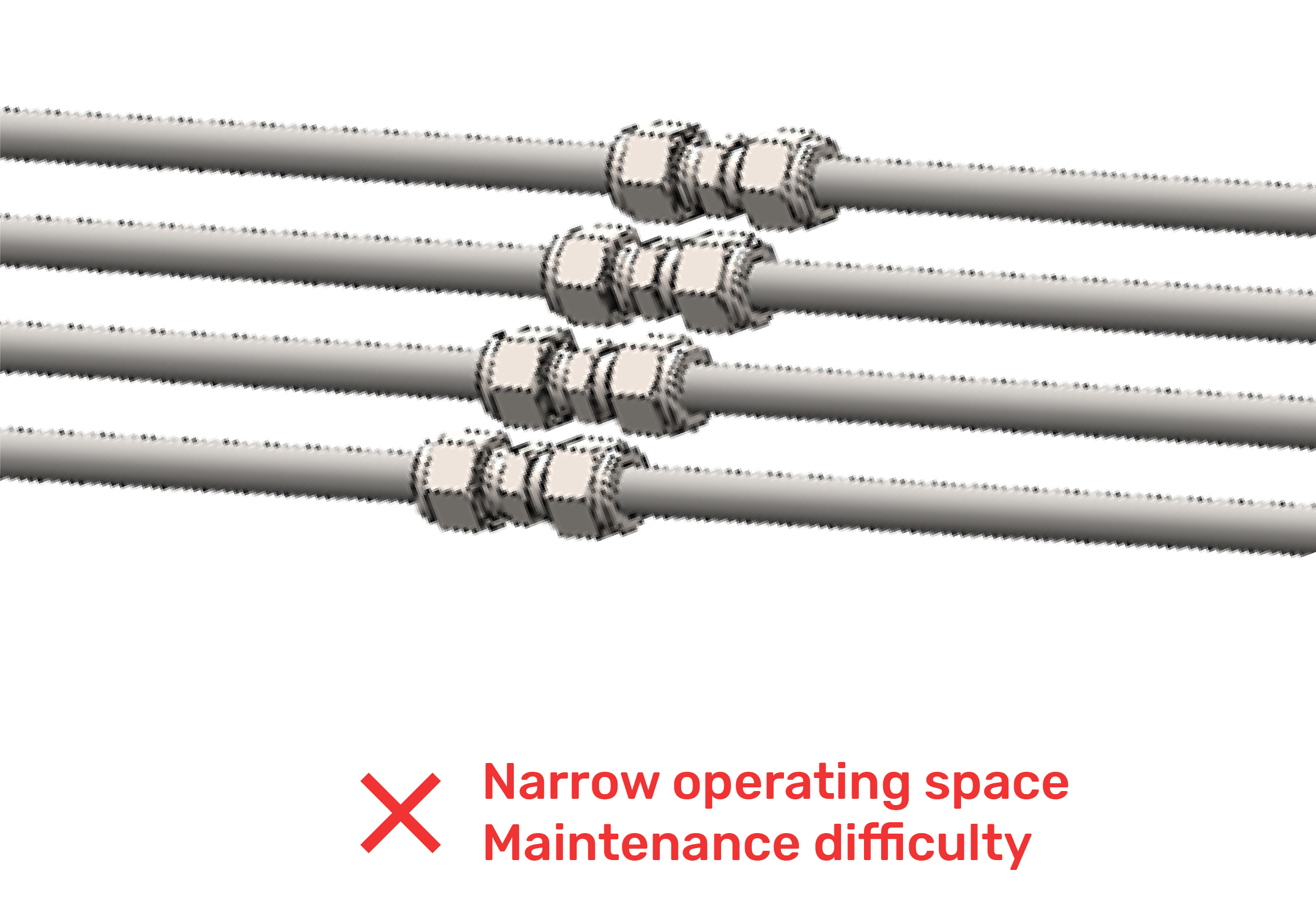

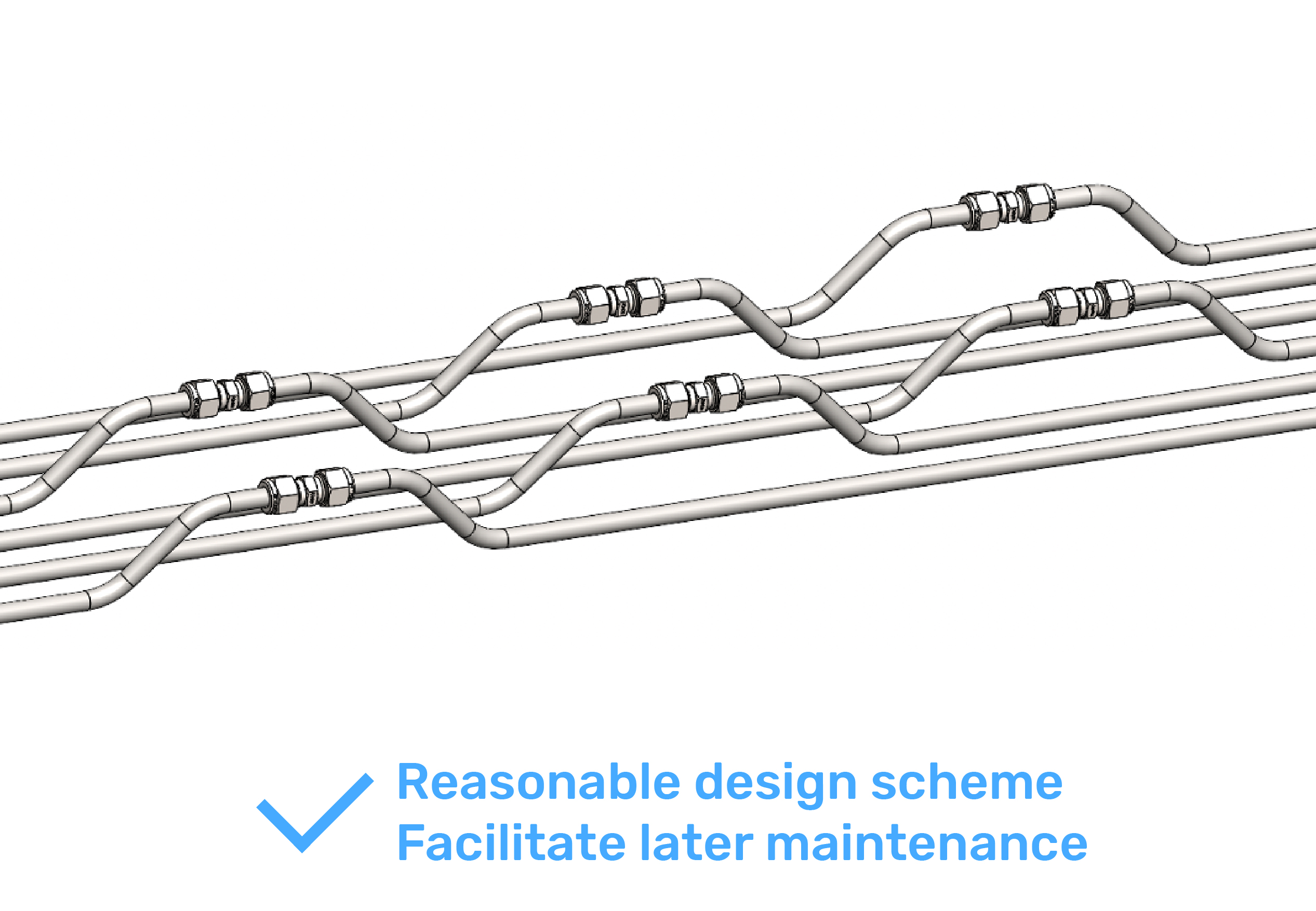

Proper installation is key to ensuring the safe and reliable operation of equipment. JPE shared practical insights into the installation of instrument tubing and tube fittings, emphasizing how seemingly minor details, such as controlling tightening torque, selecting the right sealing gaskets, and incorporating expansion loops when needed, can significantly impact a product’s service life. A single small mistake could lead to system failures or even severe safety incidents. Only through strict adherence to standards by professionals can the safety and reliability of the system be ensured.

Case Studies: Learning from Practice

To provide a more tangible demonstration of product applications and installation precautions, JPE shared several real-world case studies.

These cases not only showcased the excellent performance of JPE's products but also highlighted the importance of proper installation and the critical details that cannot be overlooked. JPE emphasized that the correct application of tubing and fittings can not only save time and costs associated with installation and maintenance but also significantly reduce safety risks arising from leaks.

JPE ensures rigorous quality control and provides comprehensive quality guarantees for its products. Through these examples, participants gained a deeper understanding of the product features and learned how to apply this knowledge to their own work, enhancing overall efficiency and safety.

The exchange meeting with CTCI ADVANCED SYSTEMS INC., a subsidiary of CTCI, not only demonstrated JPE's expertise and technical capabilities in products such as instrument tubing and tube fittings but also provided practical insights into material selection services and risk management for installation details. By emphasizing proper material selection and installation, equipment can achieve long-term stable operation, reduce potential risks, and improve overall safety standards.