JPE Industry Insights|Empowering the Petrochemical Industry towards Net-Zero Emissions

2024-09-13

Industry Knowledge Popularization

In the face of increasingly severe global climate change, environmental protection has become an international consensus. How to achieve net-zero emissions by 2060 has become a focal point of attention both inside and outside the industry.

To achieve this goal, it requires the concerted efforts of upstream and downstream enterprises in the petrochemical industry. Petrochemical industries must strengthen safety and environmental protection in their production processes, while industry chain partners provide advanced technologies and tools to support the petrochemical industry in moving towards net-zero emissions. Together, they form a highly efficient and safe ecosystem to better promote the sustainable development of society and the economy

Focusing on Safety Production and Building a High-Quality Ecosystem

Petrochemical production involves large-scale operations with numerous equipment, and the process conditions often involve high temperatures and pressures. The storage and handling of a large number of flammable, explosive, and toxic chemicals make daily production operations inherently challenging. Safety in production is of paramount importance.

As an industry chain partner in large-scale petrochemical industrial systems, assisting enterprises in controlling safety production and providing high-quality and reliable solutions for industry customers have been JPE's goals for four decades.

Over the years, JPE's product series have successively obtained numerous international certifications,such as: ISO 9001 international process management, ISO 45001 international public safety certification compliance, ISO 14001 environmental friendliness certification compliance, and ISO 15848 and ASTM F1387, which are highly recognized by the petrochemical industry.

In response to the petrochemical industry's stringent requirements for low fugitive emissions, JPE's valve series products, with their excellent performance,have been awarded the highest level A certification in the ISO 15848 international standard test since 2018, contributing to the green production of petrochemical enterprises by effectively reducing volatile organic compound (VOC) emissions.

*ISO 15848 is the current international standard for controlling fugitive emissions of volatile organic compounds (VOCs) in the petrochemical industry.

In addition, JPE's flare fittings successfully passed all basic and additional tests of ASTM F1387 in 2019 under third-party witness. The product quality has been recognized by international authorities, further consolidating JPE's leading position in the petrochemical industrial piping system field.

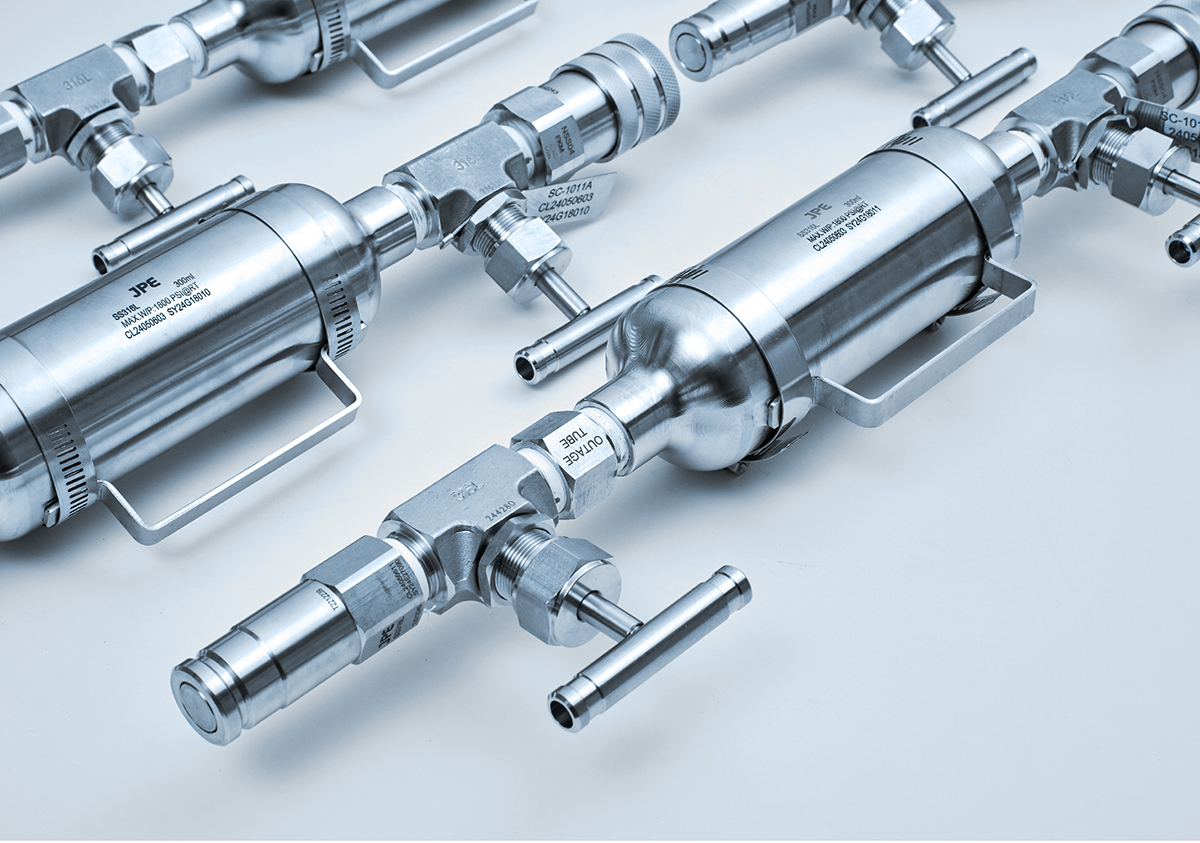

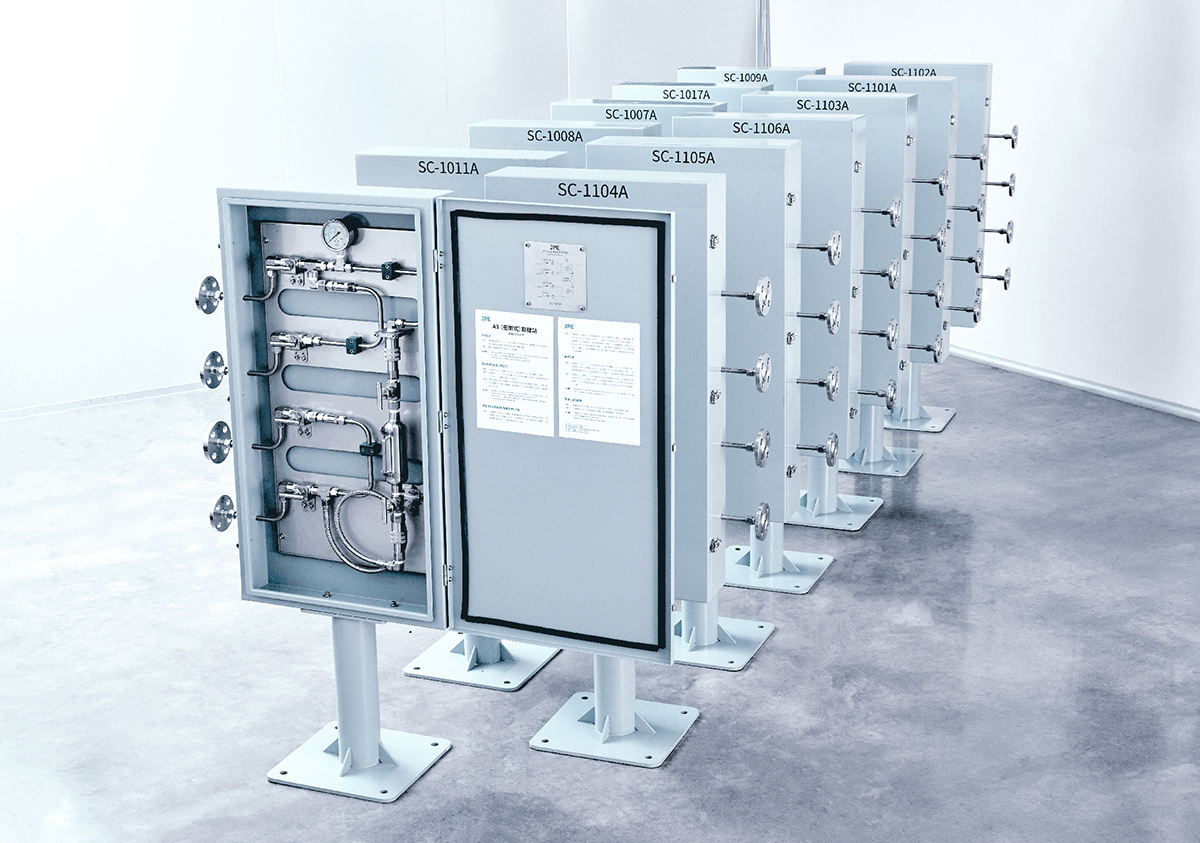

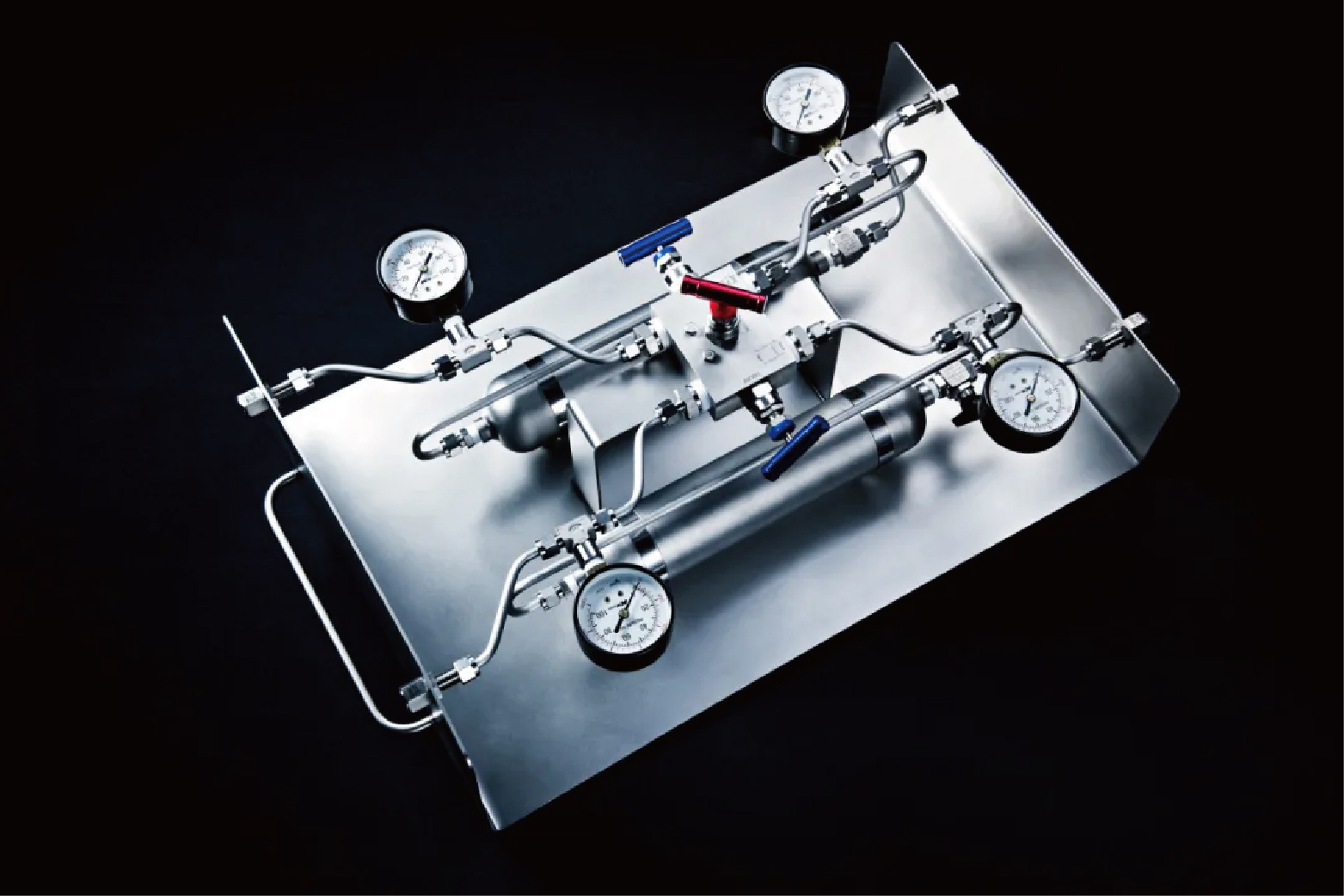

JPE always adheres to a customer-centric approach, and with its rich industry experience and strong technical capabilities, it provides customers with tailored solutions. For example, the recently delivered order for a spherical storage tank sampling system in a petrochemical storage and transportation center at a wharf. According to the special location and application medium of the project, JPE provided optimized pipeline arrangement, sampling bottle accessories, and the selection of flat quick connectors to meet the customer's special needs.

Large-scale petrochemical industrial systems have always been JPE's forte. This first requires the ability to propose professional customized solutions, and it also requires providing sufficiently high-quality system components to lay a solid hardware foundation.

In petrochemical equipment, to ensure the representativeness of samples, it is necessary to select a suitable sampling system. The sampling system designed and developed by JPE can be highly customized, and the R&D and consulting team can also assist customers in conducting design evaluation and process inspection during the sampling process, which also includes portable sampling systems.

With JPE's efforts, portable sampling systems allow sampling to be unconstrained by specific locations, and customers who need multi-point mobile sampling no longer need to be troubled by the need for on-site welding or multi-point installation, helping customers better reduce sampling time and costs.

Helping customers efficiently, quickly, objectively, easily, and representatively collect samples, avoiding biased information collected due to human or system operation factors during the sampling process, and making the final decision to ensure the quality of fluid products have always been JPE's goals.

With continuous improvement in technology and production management, JPE has long been listed on the supplier list of internationally renowned petrochemical companies, such as Taiwan China Petroleum Corporation, Sinopec, Stolt Tank Containers, Saudi Basic Industries Corporation (SABIC), Petroliam Nasional Berhad (Petronas), etc.

Taking carbon neutrality as a long-term goal is both a time challenge for the petrochemical industry itself and an opportunity for industry chain partners such as JPE to adjust their industrial structure in a timely manner, improve their core competitiveness, and help petrochemical enterprises move towards sustainable development. JPE will continue to strive to become a leading enterprise in instrumentation, valves, and fittings by consistently delivering petrochemical projects safely, reliably, and on time!